Functions of a Clarifier The final clarifier must perform two pri-mary functionsclarification and thickening. Settleable solids 610 mll suspended solids 5580 mgl.

How To Use The Business Mode Canvas A Complete Guide For Beginners Businessmodel Bmcanvas Inno Business Model Canvas Business Model Template Business Canvas

Because the process objective is more appropriately focused on the clarified liquid rather than the thickened underflow the unit operation discussed herein is referred to as primary clarification and the units themselves as primary clarifiers.

. The objective of the primary clarifier chapter in WEFs updated Clarifier Design Manual is. The weir overflow rate can be determined by. Clarification is the separation ofsolids from the liquid stream to produce a clarified efflu-ent with low effluent suspended solids ESS.

Performance design goals for primary clarifiers are typically quantified based on TSS removal efficiency which normally ranges between 50 and 75 percent and BOD removal efficiency which normally ranges between 25 and 40 percent Tchobanoglous et. Design a sedimentation unit to provide for a sewage flow rate of 4 mgd with suspended solids concentration of 300 mgL. Activated sludge clarifier design.

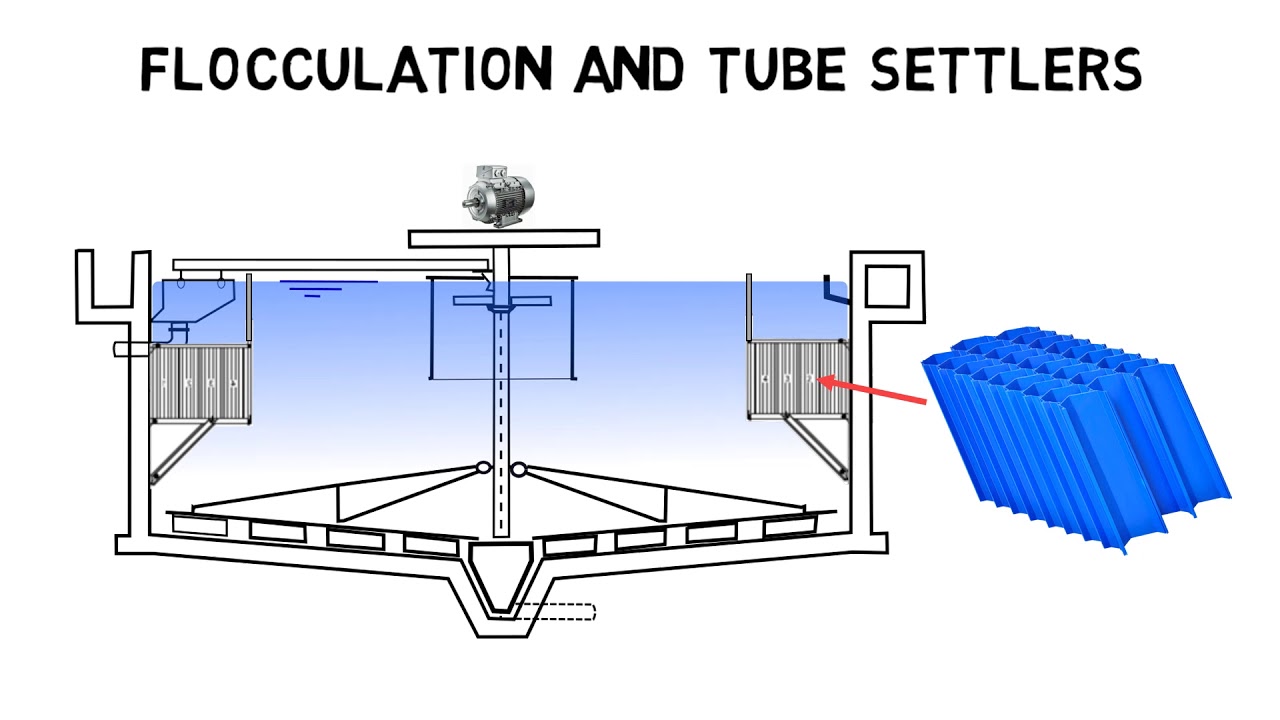

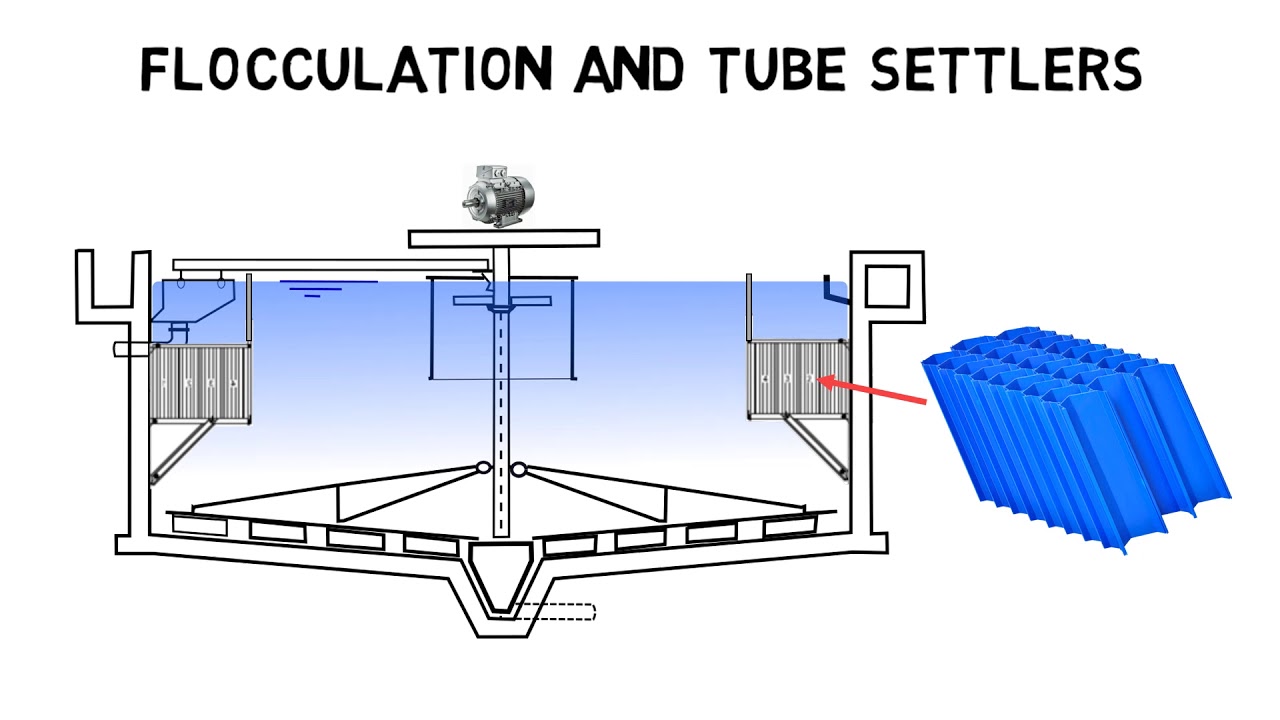

Relatively small inlet pipe and slots potential floc shear Mixed liquor fed at top of tank potential waterfall effect Impinging exits and submerged flocwell are steps in the right direction. Normally weir overflow rates of 10000 to 20000 gpdft 2 are used in the design of a settling tank. The section below illustrates a typical clarifier design.

From the primary clarifier. 8 9 Primary and secondary clarifiers essentially share the same primary function. The most widely used clarifiers are.

To remove 10 solids from water using sedimentation. Clarifiers also referenced as sedimentation tanks or settlers are an inte gral part of ever y. The central baffle in a circular clarifier with central feed normally has.

If 180 mgL suspended solids is removed by the primary clarifier how many lbday suspended solids will be removed when the flow is. A circular clarifier has a diameter of 150 ft. This tool is useful in determining the dimensions of a rectangular clarifier.

Primary clarifier sizing shall be calculated for both flow conditions and the larger surface area derived shall be utilized. In addition to the above-mentioned there are other practical design criteria of primary settling for example. To maximize performance the design of primary clarifiers must include features to.

From a sample of mixed liquor you determine. The most important sizing parameters in the primary clarifiers design are. Primary Clarifier Design Calculation.

Primary Clarifier Design Calculation The clarifiers are used in water and wastewater treatment process to remove suspended solids from water under the sole influence of gravity. Guideline and Manual for Planning and Design in Japan JSWA 2009 62 HYDRAULICS OF SLUDGE PIPELINES 621 Sludge Piping Sludge piping can be by gravity or by pumping. The clarifiers are used in water and wastewater treatment process to remove suspended solids from water under the sole influence of gravity.

Primary Clarifier Monroe Environmentals primary Circular Clarifiers are designed to receive raw wastewater after it has been prescreened to remove large objects and grit. Example 7-7 Design a clarifier -thickener for the pulp and paper wastewater using the testing data described in Figures 7-84 through 7-95 to accommodate an influent. Design of primary settling tanks is 2 hours based on the average hourly rate for the 8-.

Conventional inlet design in America January 27 2016 10 NEWEA Optimizing Clarifier PerformanceAre We Designing the Clarifiers Right. Steel shells and tanks are also available. We will 7 examine these parameters in greater detail later in the chapter.

Designalthough Types IIIand IV settling may also occur to a limited extent. SPS Engineering manufactures many types of clarifier mechanisms to best suit the clarification process. However anticipated BOD removal for wastewater containing high quantities of industrial wastewater should.

For example when primary sludge is drawn from clarifiers it is sometimes by gravity and sometimes by direct suction using pumps. 3141 Design requirements and criteria. 6 These design parameters may change slightly based on site-specific conditions.

They also have similar configurations and designs. Clarifiers are the principle mechanisms for solidliquid separation in primary intermediate intermediate and final wastewater clarification applications. A properly designed primary clarifier should remove 30 to 35 of the influent BOD.

This primary sedimentation tank will produce a homogeneous liquid capable of being treated biologically and a sludge that can be separately treated or processed. These treatment facilities are used to remove solids.

How To Design Clarifier For Primary Treatment Of Water Treatment Plant

Clarifier Basics How Do Clarifiers Work I Clarifier Design Youtube

State Point Analysis Clarifier Design Rules Youtube

Wastewater Clarifier Performance

Clarifier Effluent Troughs How To Design Launders I Overflow Weirs Youtube

0 comments

Post a Comment